Joinery Craftsmanship and Architecture

Earlier in the year Joe and Ceri visited Japan House in London to see The Carpenters’ Line, an exhibition exploring the art and heritage of woodworking in Hida Takayama; Japan.

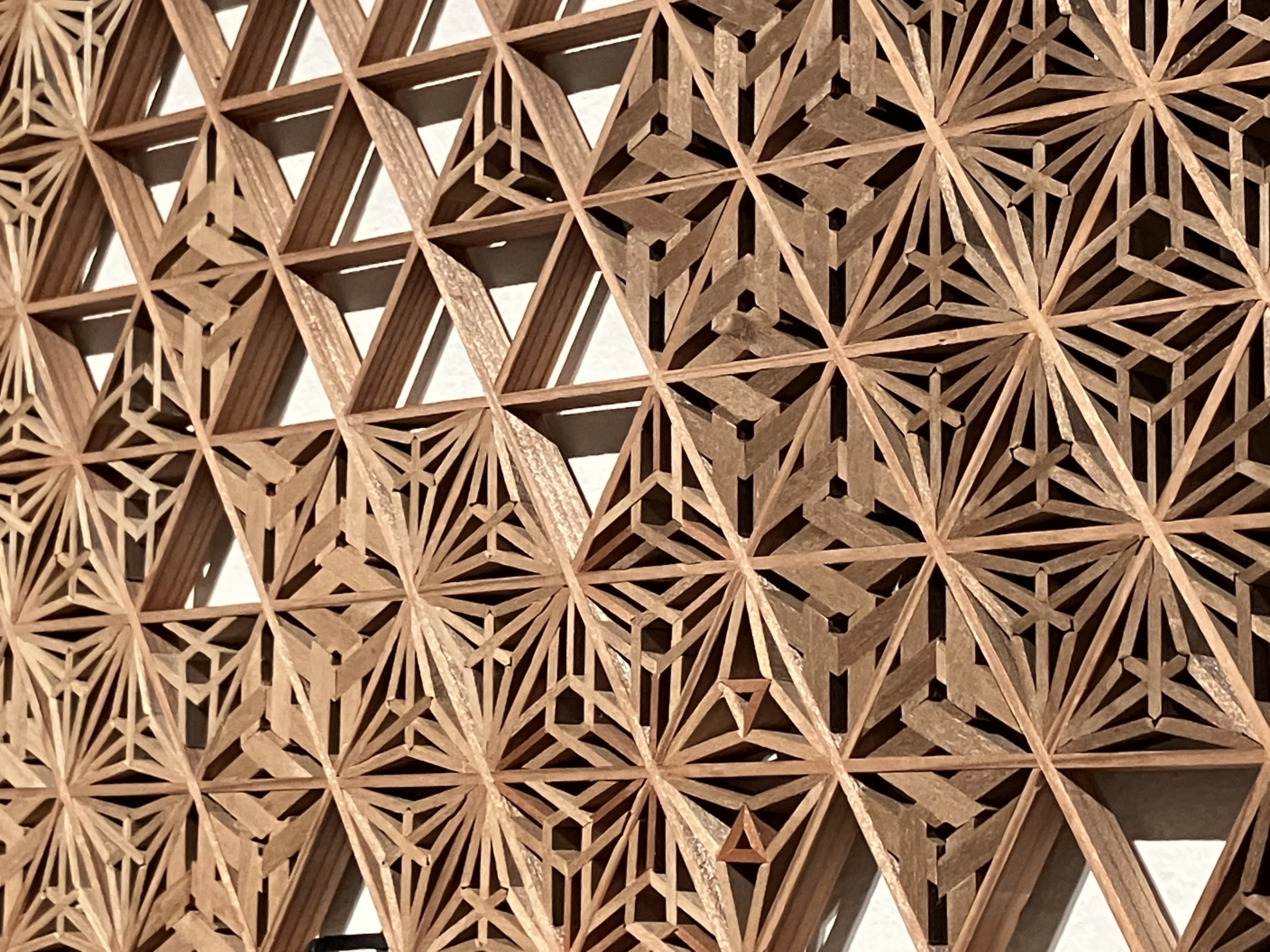

The beautifully curated exhibition showcased traditional and contemporary practices from the scale of a hand carved spoon to decorative panelled latticework room dividers and larger scale structural jointing.

An hour long demonstration from a master woodworker gave us incredible insight into the properties of the Yew wood being used and how this informs the process of carving. The expert knowledge was evident in every detail from the craftsman’s preparation and selection of the right tool to the application of the correct pressure, angle and direction in which to carve.

Collaborating closely with expert craftspeople using both traditional and new digital production techniques has always been crucial in delivering the bespoke details of Studio RHE’s projects. Whether it’s commissioning huge fine metalwork sculptures for Zil Pasyon, designing bespoke joinery elements for Wood Farm and Third Space gyms or developing structural timber jointing details for Cabot St Lucia / The Gramophone Works / Republic we aim to build on our detailing knowledge through collaboration.

Alongside the expertise of the team physically making our projects we work closely with material suppliers from around the worlds to source the right materials for each project. This selection needs to take into account aesthetic and tactile qualities but also, crucially, technical and performance characteristics that will impact decisions on both production detailing as well as use and maintenance.

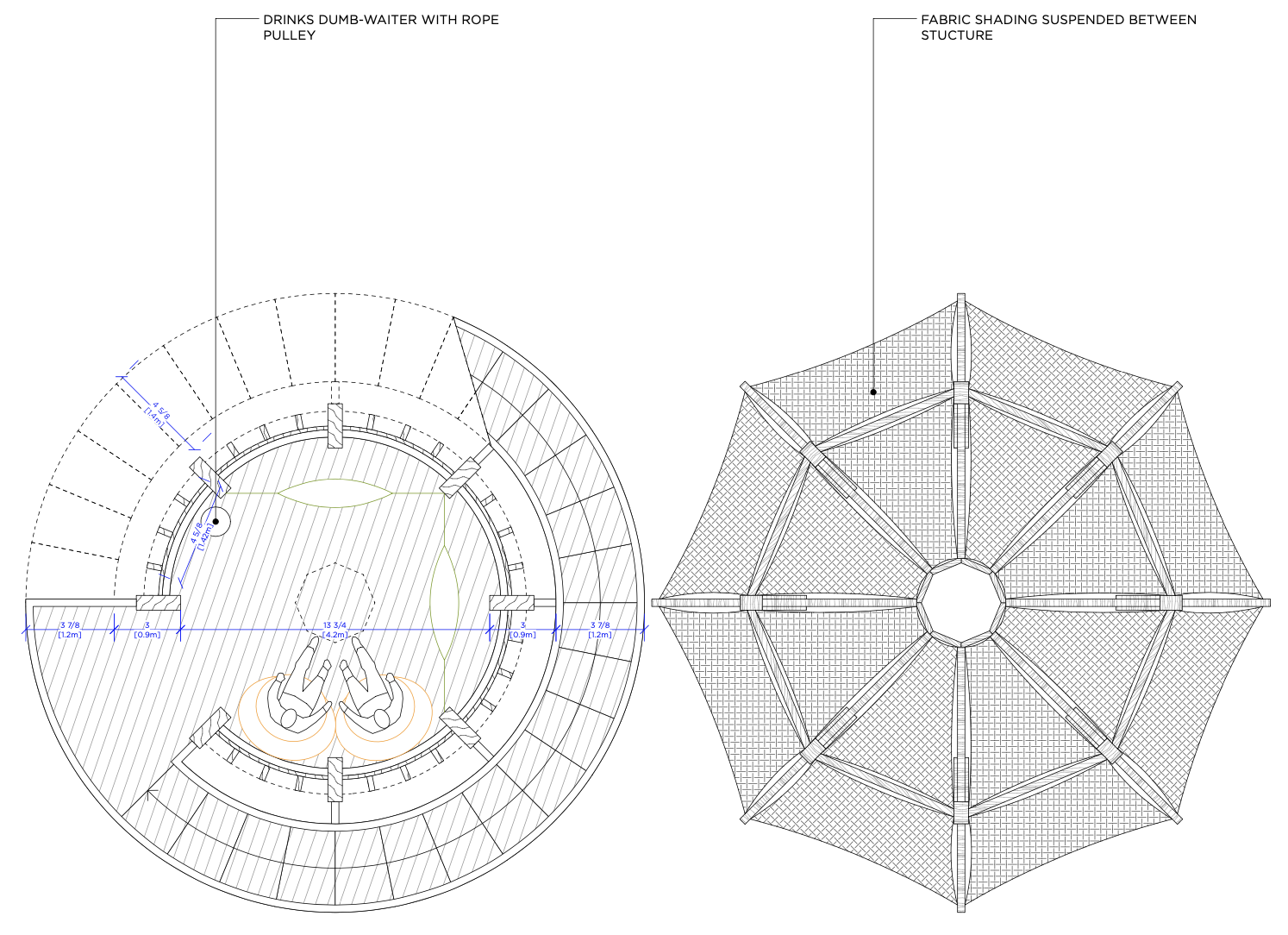

For Cabot St Lucia we worked with specialist structural timber fabricators to choose a suitable timber. Environmental considerations of sunlight and salty Atlantic winds were taken into account alongside durability from insects. Structurally the timber had to support the physical weight of the roof and glazing while also standing up to hurricane winds and the possibility of earthquakes.

In conjunction with the fabricator and structural engineers we were able to design junctions that used timber’s intrinsic strength while keeping the beautiful wood grain surface exposed. A combination of tenon joints and steel plates concealed within wood pockets achieved the required strength while still celebrating the natural material.

For our current projects in the British Virgin Islands we’re working with specialist timber suppliers who will be prefabricating parts of the building in Bali. Ranging from handrails and staircases up to whole roof structures each piece will be built in its entirety before being disassembled for transport.

Prefabrication allows work to be carried out while construction on site is ongoing and to be installed quickly and efficiently. Importantly it also means that the most skilled craftspeople can operate from the controlled space of their own workshops and produce higher quality work to finer tolerances.

As a studio we try to always visit the workshops to check on the progress but also to improve our understanding of materials and production techniques. This knowledge learned through collaboration with expert craftspeople gives us an appreciation of the whole process from material selection to fabrication and install on site.

Seeing expertly crafted joinery up close, whether it’s in the workshop, on site or at an exhibition, keeps developing our knowledge of traditional and contemporary craft.